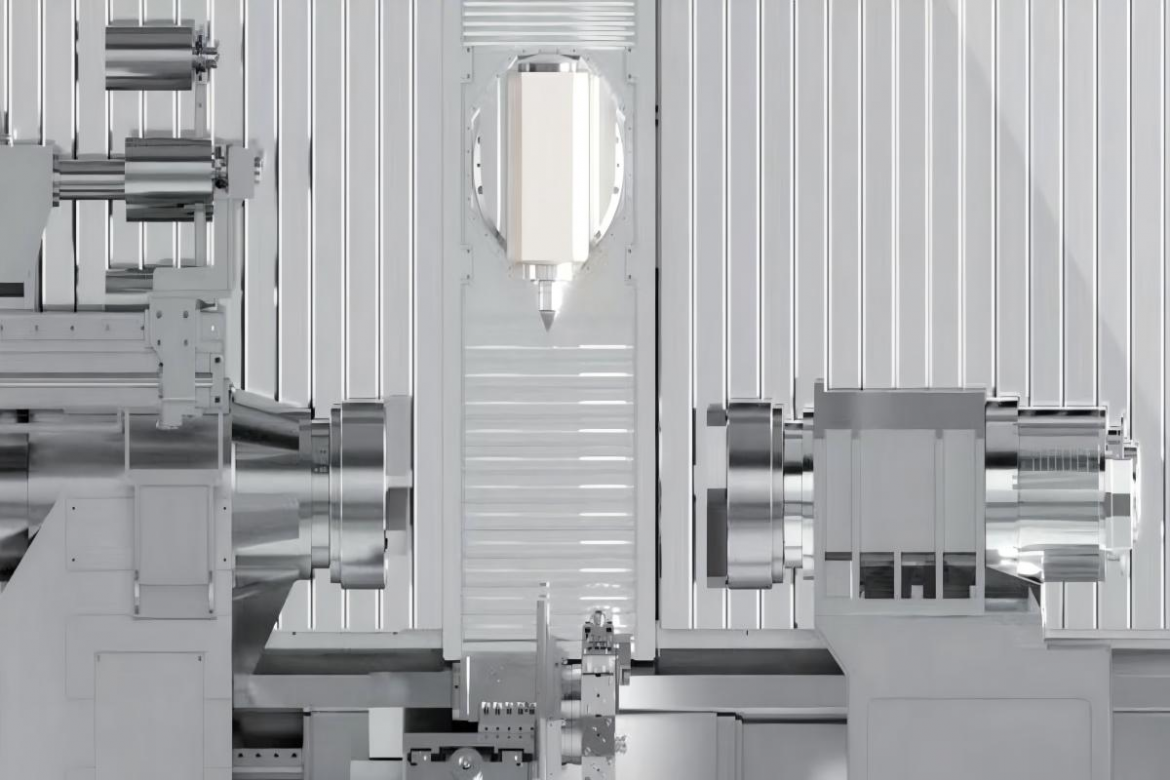

Automating CNC machines has become a priority for manufacturers aiming to improve precision and throughput. Leichman provides advanced CNC machining solutions designed to streamline production processes while ensuring consistent quality. Their LKX1250 – Five-Axis Turn and Mill Center demonstrates true 5-axis integration, allowing simultaneous multi-surface machining with ±0.001° positioning. This feature is especially beneficial for high-precision operations, such as gear cavity finishing in automotive and industrial applications. By implementing automation, companies can reduce manual intervention, minimize errors, and increase overall productivity.

Integrating CNC Automation with Advanced Equipment

To achieve effective CNC automation, manufacturers can leverage systems like the LKX1250 – Five-Axis Turn and Mill Center. The machine’s automatic workpiece transfer enables dual-spindle coordination, which streamlines complex setups and supports unmanned night shifts. This functionality is particularly valuable for Tier-1 automotive plants where continuous operation is critical. By integrating CNC machining solutions into the workflow, businesses can maintain consistent production schedules while reducing labor dependency and potential bottlenecks.

Maximizing Flexibility with High Tool Capacity

A key factor in CNC automation is the ability to handle diverse parts without frequent tool changes. The LKX1250 offers a high tool capacity with over 60 tools onboard, accommodating a wide variety of geometries efficiently. This capability allows manufacturers to implement flexible production strategies, responding quickly to varying product demands. When paired with Leichman’s proactive support services, including 24-hour technical consultation and tailored maintenance, these machines achieve reliable, high-efficiency operation across different industrial scenarios.

Conclusion: Benefits of CNC Machine Automation

In conclusion, automating CNC machines through solutions like Leichman’s LKX1250 ensures precision, flexibility, and consistent output. By combining true 5-axis machining, automatic workpiece handling, and extensive tool capacity, businesses can implement effective CNC machining solutions and CNC automation practices. These advantages not only enhance operational efficiency but also support industrial clients in meeting tight production schedules, minimizing downtime, and reducing inventory pressures.