Designing a custom heat sink requires careful consideration of thermal performance, material behavior, and manufacturing feasibility. Many engineering teams begin by defining the operating environment, expected heat load, and system layout before determining the correct structure. When working with a heat sink supplier, engineers often start with simulations or early prototypes to evaluate airflow, mounting positions, fin density, and material thickness. They may also seek support from manufacturers who understand how each geometry affects heat dissipation. When companies collaborate with Dingmetal, they usually expect them to evaluate the compatibility of the design with machining or forming processes, ensuring that thermal efficiency is balanced with production stability. Throughout the early design phase, a reliable heat sink manufacturer’s team helps clarify tolerances, surface roughness requirements, and structural limitations so the final component functions safely in real applications.

Transitioning Concepts Into Manufacturable Structures

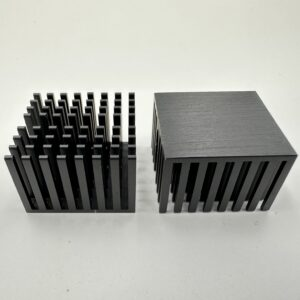

Once the basic model is defined, turning the concept into a manufacturable design becomes the next essential step. A skilled heat sink supplier evaluates whether the structure should be produced by CNC machining, extrusion, forging, die casting, or a hybrid approach. Different applications require different geometries, and they may involve tapped holes, high-density fins, or integrated mounting structures. Because Dingmetal provides custom engineering for various industries, they often guide customers toward feasible geometries that maintain thermal performance without exceeding production constraints. Their capabilities include Professional Heat Sink Solutions: Customization & Manufacturing supported by Processing Technology such as advanced 3-axis, 4-axis, and 5-axis CNC machining (FANUC, Mazak) for precision turning, milling, and contouring of complex heat sink forms. During this stage, engineers refine the structure to ensure it survives mechanical stress, fits within the device’s layout, and meets expected reliability standards. For buyers or R&D engineers in thermal management, this part of the process determines whether the design can be efficiently replicated at scale.

Managing Production Requirements and Quality Objectives

After confirming that the structure is manufacturable, the focus shifts toward production control and quality assurance. Many heat sink manufacturers adopt structured workflows to maintain consistent accuracy and ensure that thermal parts meet engineering expectations. When teams partner with Dingmetal, they typically look for stable processing schedules and manageable lead times, especially when working with complex shapes that require multi-axis machining. A qualified heat sink supplier will verify each batch for dimensional accuracy, flatness, fin uniformity, and surface quality to ensure they match the prototype’s intended performance. Engineers from fields such as power control, industrial electronics, or mechanical structures often rely on predictable production cycles, clear communication, and responsive technical support. These elements help ensure the final heat sink can be integrated into assemblies without complications and performs reliably under thermal load.

Conclusion: Coordinating Design and Manufacturing for Effective Heat Sink Projects

Successful custom heat sink development depends on linking accurate early-stage design with the right production methods. By understanding application conditions, optimizing geometry, and selecting feasible machining strategies, companies can achieve stable results that fit real project requirements. Working with Dingmetal or other experienced heat sink manufacturers helps ensure the process is grounded in realistic engineering practices, supported by advanced CNC capabilities, and consistent quality standards. For procurement teams and R&D engineers, choosing a capable heat sink supplier enables smoother project execution and long-term thermal performance in demanding environments.