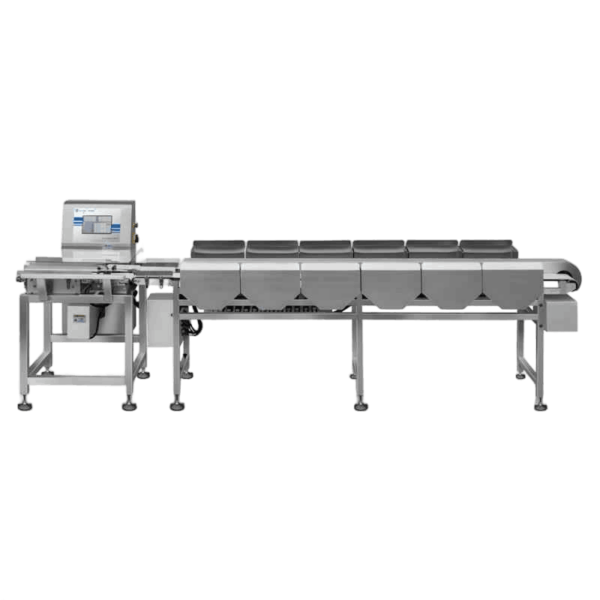

Across multiple sectors, the integration of precision automation drives significant gains in quality and efficiency. WEIGHT SORTING technology, which utilizes high-precision sensors to categorize items by mass, offers measurable advantages in several key industries. The application of a weight sorting machine solves distinct operational challenges related to quality control, portioning, and regulatory compliance.

Agricultural and Fresh Produce Processing

In the agricultural sector, consistency in product size and weight directly influences market value and consumer perception. A weight sorting machine enables the precise categorization of fruits, vegetables, and seafood. This automated process ensures uniform packaging, optimizes yield by minimizing underweight and overweight portions, and enhances grading accuracy. This technology supports growers and processors in meeting strict customer specifications.

Food Manufacturing and Portion Control

For packaged food producers, maintaining strict portion control is a critical financial and compliance requirement. A WEIGHT SORTING machine verifies the weight of packaged goods, ensuring they meet labeled claims and reducing product giveaway. This application is vital for items like frozen meals, baked goods, and meat products, where cost control and regulatory adherence are paramount for brand integrity.

Pharmaceutical and High-Value Goods Production

The pharmaceutical industry requires absolute accuracy in packaging and component handling. Here, a WEIGHT SORTING machine performs a critical quality assurance role. It can verify the fill weight of bottles, count capsules by weight, and ensure the presence of all components in a kit. This non-destructive check provides a final safeguard, ensuring product integrity and patient safety before distribution.

The utility of a WEIGHT SORTING machine extends to any industry where mass is a key indicator of quality, value, or compliance. By providing objective, data-driven sorting, this technology allows businesses to enhance product standardization, reduce waste, and strengthen their quality assurance protocols. The WEIGHT SORTING process delivers a clear return on investment through improved operational control.