Nitrogen is a crucial element in countless industrial processes, ranging from food packaging and pharmaceuticals to electronics manufacturing and chemical blanketing. Ensuring a reliable and cost-effective supply of high-purity nitrogen is paramount for businesses across these sectors. This is where a robust nitrogen generator system becomes indispensable. Rather than relying on expensive and often inconvenient nitrogen cylinders or bulk liquid nitrogen deliveries, many companies are turning to on-site nitrogen generator solutions. Lingyu, a prominent name in industrial gas solutions, offers a diverse range of Lingyu nitrogen generator technologies designed to meet varied purity and flow rate requirements.

Pressure Swing Adsorption (PSA) Nitrogen Generators

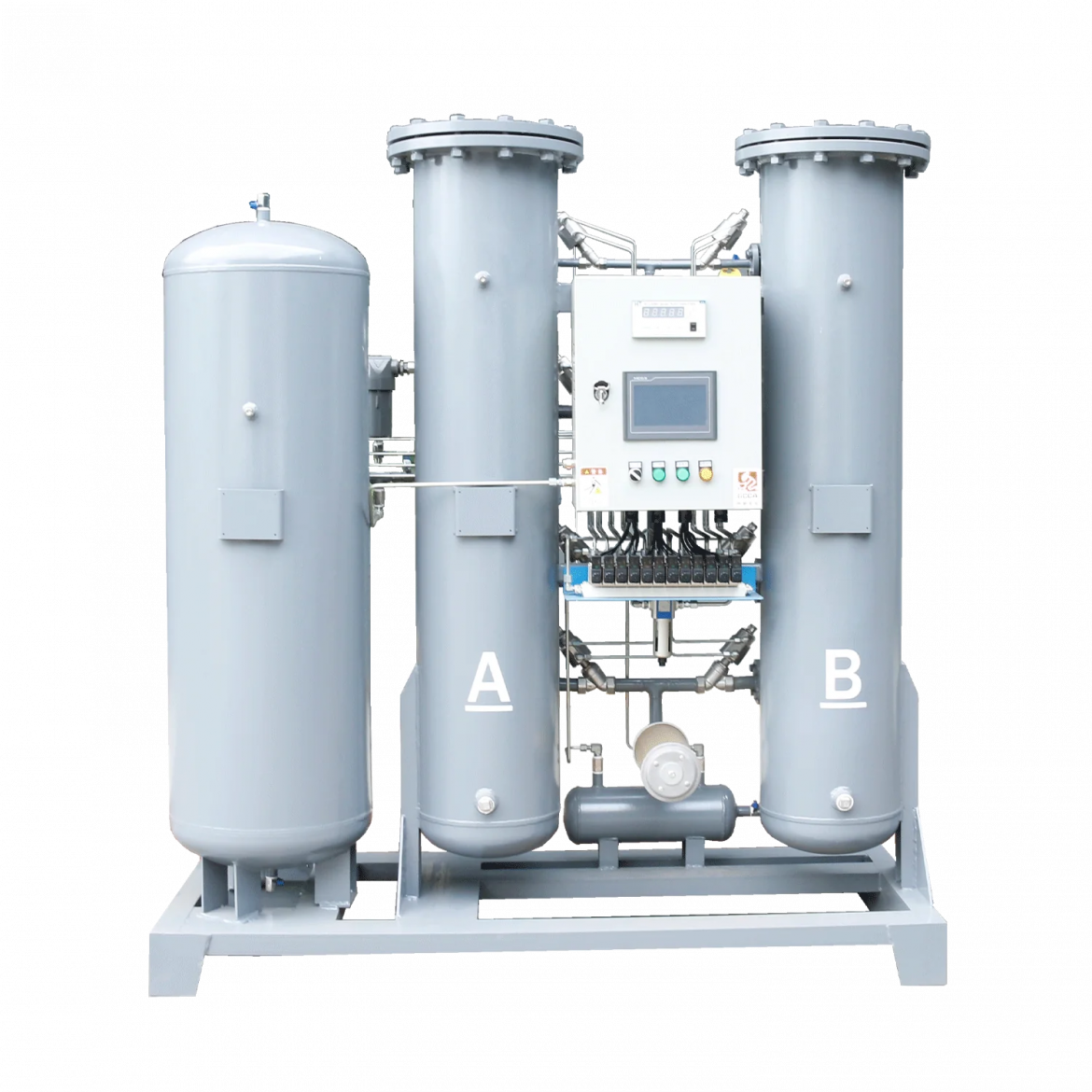

One of the most widely adopted technologies for on-site nitrogen generation is Pressure Swing Adsorption (PSA). PSA nitrogen generator systems operate by selectively removing oxygen, argon, and other trace gases from compressed air, leaving behind a stream of high-purity nitrogen. The principle relies on adsorbent materials, typically Carbon Molecular Sieves (CMS), which have a greater affinity for oxygen molecules than nitrogen at higher pressures.

The typical PSA nitrogen generators consist of two towers filled with CMS. Compressed air passes through one tower, where oxygen and other impurities are adsorbed, allowing purified nitrogen to pass through to a buffer tank. When the CMS in the first tower becomes saturated, the airflow is switched to the second tower. Simultaneously, the first tower is depressurized, releasing the adsorbed gases to the atmosphere. This cycle of pressurization and depressurization, or “swinging” between high and low pressure, allows for continuous nitrogen production. Lingyu’s PSA nitrogen generator models are engineered for efficiency and reliability, offering a cost-effective solution for applications requiring nitrogen purities typically ranging from 95% to 99.999%. The robust design of a Lingyu nitrogen generator ensures consistent performance and minimal maintenance, making it a popular choice for a wide array of industrial uses.

Membrane Nitrogen Generators

Another prevalent method for nitrogen generation is through membrane technology. Membrane nitrogen generator systems utilize hollow fiber membranes that selectively permeate oxygen, water vapor, and other impurities, while allowing nitrogen molecules to pass through unhindered. Compressed air is introduced into a bundle of these semi-permeable membranes. The different sizes and shapes of molecules, combined with their solubility in the membrane material, dictate their passage rate. Smaller, faster-moving molecules like oxygen and water vapor pass through the membrane walls and are vented as waste gas, while larger, slower-moving nitrogen molecules remain inside the hollow fibers, exiting as purified nitrogen.

Membrane nitrogen generator units are particularly well-suited for applications where lower nitrogen purities (typically 95% to 99%) are acceptable, and where a compact, quiet, and low-maintenance solution is desired. They are often favored for their simplicity of operation and their ability to function effectively in challenging environments. The modular design of many membrane-based Lingyu nitrogen generator systems also allows for easy expansion as nitrogen demand increases. For processes like fire prevention, tire inflation, and some food packaging applications, a Lingyu nitrogen generator employing membrane technology provides a dependable and energy-efficient source of nitrogen.

Cryogenic Nitrogen Generators

For applications demanding extremely high purity nitrogen (up to 99.9999% or even higher) and very large flow rates, cryogenic air separation is the preferred method, delivered by a cryogenic nitrogen generator. This process involves cooling air to extremely low temperatures (below -170°C or -274°F), which causes it to liquefy. Since nitrogen and oxygen have different boiling points, they can be separated through fractional distillation. Liquid air is progressively warmed, and as each component reaches its boiling point, it vaporizes and is drawn off separately.

While more complex and energy-intensive than PSA or membrane technologies, a cryogenic nitrogen generator is unmatched in its ability to produce ultra-high purity nitrogen in immense volumes. These systems are typically found in large industrial complexes, such as steel manufacturing, semiconductor fabrication, and major chemical plants. For operations where absolute purity and massive continuous supply are non-negotiable, a Lingyu nitrogen generator based on cryogenic principles would be the ultimate solution, though Lingyu’s primary offerings focus on more accessible PSA and membrane solutions for a broader range of industrial needs.

Choosing the Right Lingyu Nitrogen Generator

When selecting a nitrogen generator, several factors must be considered, including the required nitrogen purity, flow rate, budget, available space, and operational environment. Each type of nitrogen generator offers distinct advantages. For instance, if your application demands purities up to 99.999% and a cost-effective solution for a variety of flow rates, a PSA Lingyu nitrogen generator is likely the ideal choice. These generators are known for their efficiency and long operational life, delivering consistent performance for critical industrial processes.

Conversely, if your purity requirements are slightly lower (e.g., 95-99%) and you prioritize a compact, quiet, and simple-to-operate system, a membrane-based Lingyu nitrogen generator might be more suitable. These systems are easy to integrate into existing infrastructures and require minimal intervention. Lingyu’s commitment to innovation ensures that clients receive a nitrogen generator solution perfectly tailored to their specific operational demands, optimizing efficiency and reducing overall costs associated with nitrogen supply. By investing in a high-quality Lingyu nitrogen generator, businesses can gain greater control over their gas supply, enhance operational safety, and achieve significant financial savings over time compared to external nitrogen sourcing. Lingyu’s comprehensive range of nitrogen generation solutions underscores its position as a leader in providing reliable industrial gas technology.