The advancement of lithium battery automation equipment is revolutionizing the energy storage industry, offering manufacturers a range of benefits that enhance productivity, efficiency, and cost-effectiveness. As the demand for high-performance batteries continues to grow, investing in automated solutions, such as specialized coating machines, becomes critical for competitive edge.

Enhanced Efficiency with Double-Layer Super-E Coating Machines

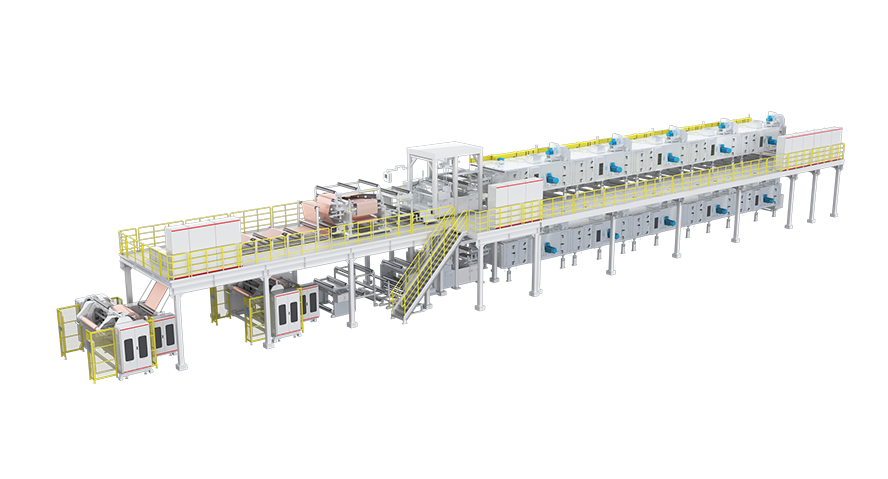

One of the standout innovations in lithium battery manufacturing is the Yinghe double-layer super-E coating machine. This cutting-edge equipment employs an E-shaped electrode layout, allowing the electrode to undergo two drying processes within a single oven. This configuration not only reduces the overall length of the production line by more than 35% but also significantly boosts oven efficiency. By streamlining the coating process, manufacturers can produce higher quality electrodes faster, directly impacting output and profitability.

Space and Energy Savings

Beyond efficiency, the advantages of advanced battery coating machines extend to spatial and energy resources. The new design results in a 35% reduction in equipment footprint, making it possible to optimize workspace and reduce overhead costs associated with larger machinery. Furthermore, the energy consumption associated with these machines is reduced by over 35%, contributing to lower operational expenses and a smaller carbon footprint. This becomes especially advantageous for companies looking to enhance their sustainability efforts while maintaining high productivity.

Reduced Maintenance and Labor Costs

Automation in the battery manufacturing process also leads to a decrease in maintenance personnel requirements by approximately 30%. By integrating automated systems like the battery coating machine, businesses can focus on strategic operations rather than routine maintenance tasks. This shift allows for a leaner workforce and the reallocation of human resources to more critical areas of production.

Partnering with Industry Leaders for Optimal Solutions

Investing in battery automation equipment not only improves operational efficiency but also enhances the overall manufacturing process. Collaborating with reputable suppliers, such as Yinghe, ensures access to high-quality, innovative machinery tailored to meet the evolving demands of lithium battery production. With their expertise in battery coating machine wholesale offerings, Yinghe is committed to helping manufacturers achieve superior production capabilities while unlocking significant cost savings. Embracing automation is not just a trend; it’s a path to future-proofing operations in the competitive battery manufacturing landscape.